Temperzone engineers have extensive experience and knowledge to provide solutions to suit different project requirements.

Our advanced systems are designed and manufactured by local Research and Development, meaning you can always depend on easily accessible advice, technical support, installation, and service repair information.

With Temperzone products continually evolving to provide higher levels of efficiency, comfort, and better air treatment, you can be comforted knowing that Temperzone will be there throughout the entire product life cycle to provide continuous product support.

There are many factors to consider before applying a particular product to various applications such as noise, power supply, airflow, water flow, static pressure, and air treatment to name a few.

There are really no shortcuts to achieving good design and functionality. The below information provides key points of consideration relating to installation and design:

Noise Isolation

Flexible ducting installation guide

Applications manual

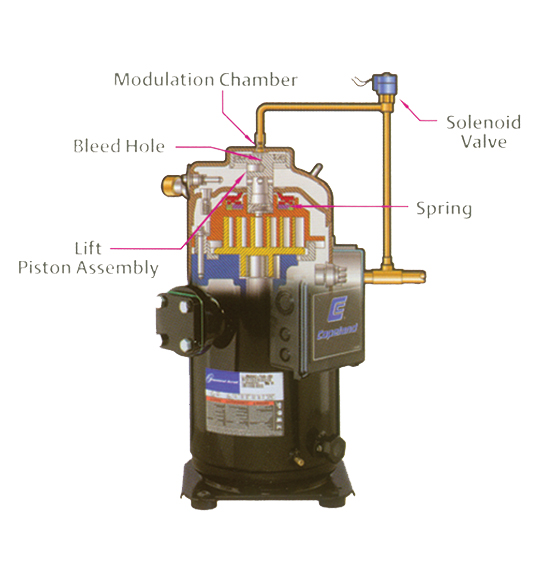

Temperzone uses world-renowned Copeland compressors in a large number of its air conditioning systems. Copeland's Digital Scroll was the first compressor to deliver a capacity range from 10% to 100% without the use of inverters.

Digital compressors ensure high efficiency through a unique feature termed 'axial compliance'. This allows the fixed scroll to move incrementally in the axial direction to ensure that fixed and orbiting scrolls are always loaded together with optimal force.

The compressor is controlled variably by a 0–10 volt DC signal that can be supplied either by a BMS system, a sophisticated controller or Temperzone's optional TZT-100 Controller.

How digital scroll compressors work

2004

Approved installer requirements (Updated for R410A – supersedes issue 02/96) (Split systems)

2001

Problems Associated with Standard Air Conditioners to High Percentage Fresh Air Systems (OSA/ISD and OPA)