How do poorly selected temperature & humidity setpoints impact energy consumption & room conditions?

What are the implications of poorly selected temperature & humidity setpoints on energy consumption and their desired effect on room conditions?

A key challenge facing the built environment today is rising operational costs, an issue becoming more prevalent with the emerging energy crisis. The drive to optimise buildings has never been more important, finding efficiency gains through simple observations and learning from poor practice not only reduces cost but also positively impacts carbon emissions.

The findings observed from the two sites presented in this study illustrate that where you set your temperature and humidity setpoints will make a considerable impact on energy consumption, and when set incorrectly can also adversely affect the comfort conditions when applied in a retail supermarket.

Application

- Retail and Humidity control

Observations

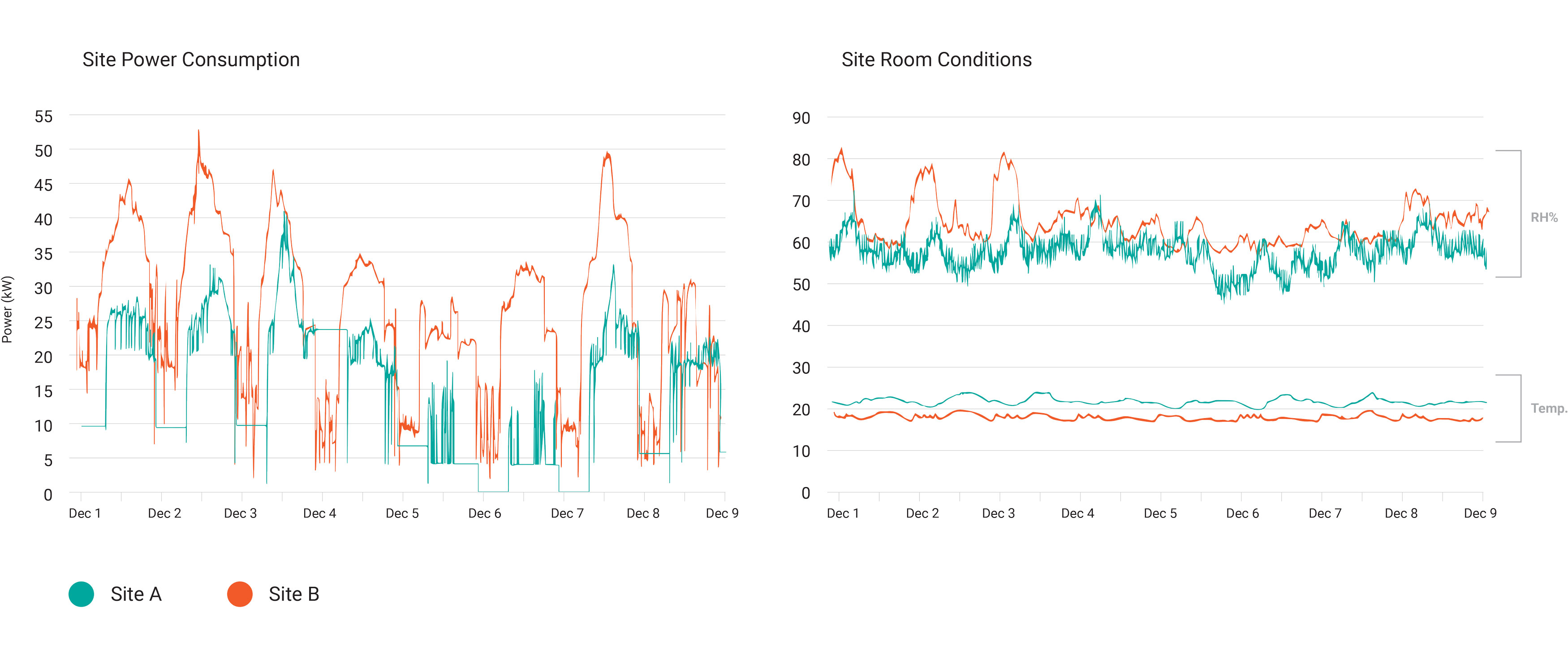

- Data extracted from 1 Dec 2021 to 8 Dec 2021

- Package units on both sites are OPA 1400 ECO Ultra with reheat coils

- Site A serves a supermarket with a cooling temperature setpoint of 23.5°C & 55% RH setpoint

- Site B located 20 km away is also a supermarket with setpoints of 19°C & 55% RH

- Both systems are identical in capacity and both approximately equivalent in floor space

- Site B room temperature setpoint is 4.5°C lower than Site A

- Site B struggles to maintain RH% setpoint

- Site B is consuming 55% more energy than Site A

Air Properties

- Moisture removal rate based on air movement of 7,000 l/sec

- Site A @ 23.5°C & 55% RH = 15 g/sec or 54 l/hr

- Site B @ 19°C & 55% RH = 10.7 g/sec or 38.7 l/hr

Some Background

Intuitive compressor control - Floating Suction Pressure

When deciding on the most suitable room setpoints it is important to understand that the Humidity Intelligence series use the setpoint values as the fundamental part of the control strategy. The controller’s logic converts the setpoint values of temperature and humidity into the dew point value based on air properties, the program then offsets this value based on the current comfort mode which is determined by the room conditions, for example if the room temperature is above setpoint while the room humidity is below setpoint the unit would then be running in 'High sensible cooling' which would conservatively offset the dewpoint value. The resulting value then defines the compressors target suction pressure since refrigerant properties share a direct relationship with temperature. The lower the suction pressure setpoint the more the compressor will work in order to achieve the target setpoint. This may mean the compressor runs at higher RPMs for longer durations or runs at lower RPMs for shorter durations, which all depends on the load within the space.

The intent behind this logic is to precisely match the refrigeration load based off the room setpoints, and condition the air to the minimum requirements through the day and across the seasons.

By understanding this basic design intent it will be understood that if the setpoints are aggressively set then the unit’s operation will operate more frequently and harder, this will then consequently affect power consumption with little part load gains.

The Key Findings

Site B is not performing to set point, in fact the unit is drawing 55% more power than Site A while not maintaining RH% setpoint. It is also observed that the comfort conditions are poor considering the store temperatures move between 17°C and 19°C during store opening hour periods.

Analysing the moisture removal rate of the equipment based on airflow, it is clear that maintaining lower temperature conditions adversely impacts power consumption and fails to achieve the desired humidity conditions.

The observations should then lead to the following question, why does site B require a lower temperature setpoint?

The obvious answer to the question should be simple, there is no reason why the setpoint is low. it is a common perception that setting a lower setpoint will remove more moisture out of the air, this is not the case here.

Where does Reheat fit in the operation?

Reheat coils are fitted to both sites and are operating throughout this period. It is observed that the reheat coils are increasing return air temperatures to maintain higher supply temperature. This operation prevents overcooling the room which would result in regular off-cycles which would lead to poor control of humidity.

Quantifiable Savings

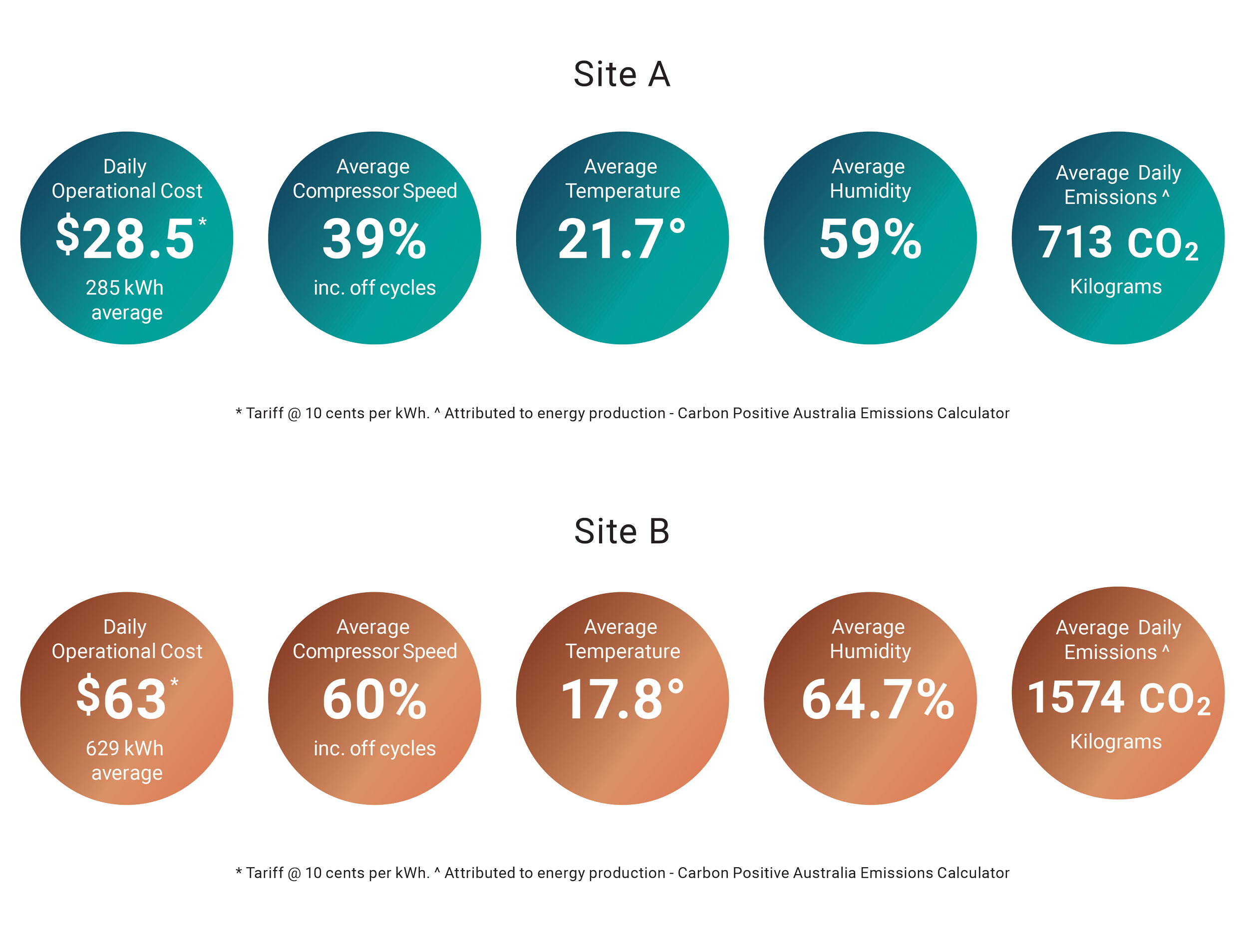

If Site B was to adopt the same temperature and humidity setpoints as Site A, they would potentially reduce daily operational energy costs by 55% from $63.00 to $28.50*, this is due to the benefits of part load operation, particularly of the inverter compressors where we see an average speed drop from 60% down to 39%. All this while maintaining a RH% closer to setpoint.

Given the considerable difference in energy consumption between the two sites over this period, compared to Site A, we see that Site B accounts for 860 kilograms more CO2 emissions each day from power generation.

How we help you

Talk to us about selecting the right product for the right application. Our team of passionate and enthusiastic individuals offer advice and support on all our product lines and can recommend the best control strategy or system setup tailored to any application. You may also choose to have an expert attend site to start up the equipment, and also train your staff to ensure effective project delivery.

* Tariff @ 10 cents per kWh. ^ Attributed to energy production - Carbon Positive Australia Emissions Calculator