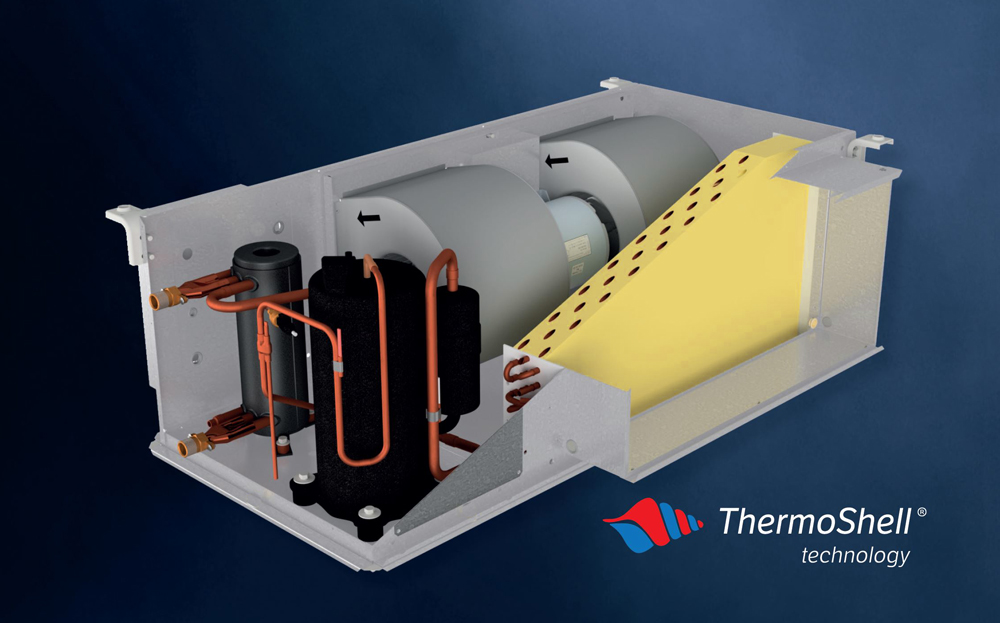

ThermoShell® technology is Temperzone’s high performance, compact heat-exchanger for refrigerant and water systems.

ThermoShell enables considerably lower water flow rates and water pressure drops to be accommodated by the system, with minimal effect on duty and efficiency. This allows for a reduction in water piping and pump sizes and associated installation costs to considerably reduce capital and operating costs.

The effect of a decreased water flow rate through a non EC Fan model HWP 59 with ThermoShell® was measured under laboratory conditions to examine the overall effect on duty and EER.

It was shown that increasing the temperature differential across the condenser to 9°C by significantly decreasing the water flow rate had only a minimal effect on the duty and EER of the unit (from 3.65 to 3.43).

Also, individual units will run much more efficiently when only a proportion of the units are operating at any one time. Therefore, real world efficiencies will be greater than design efficiencies.

Water cooled condenser networks are typically designed to have a 5°C temperature difference across the condenser under design conditions of OAT 35°C, IAT 27/19°C, EWT 30°C. In practice, however, the air-conditioners are very rarely operating under these conditions, with all of the units on a water loop simultaneously operating. For the vast majority of the time, only a proportion of the units will be operating. In addition, water sourced units can be operating in heating and cooling modes simultaneously, which moderates the water loop temperature.

There are considerable savings in capital costs in the installation of a system if the flow rate, under design conditions, can be reduced. A doubling of temperature differential across the condenser results in a halving of the flow rate, and a quarter of the pressure drop the pump has to overcome. This allows the pipe and pump sizing to be reduced, which results in the lowered capital cost.

The advantages of an increased design temperature differential needs to be balanced with the reduction in the duty and the efficiency of the unit under design conditions. The effect of decreased flow rate through the ThermoShell was measured under laboratory conditions.

A non EC Fan HWP 59 was tested under typical conditions of OAT 35°C, IAT 27/ 19°C, EWT 30°C with LWT ranging from 35-45°C.

A 5°C increase in LWT results in water flow rates down from 0.36 l/s to 0.18 l/s and a pressure drop decrease from 42kPa to 10kPa. This graph illustrates no significant corresponding change to duty power & EER.

A non EC Fan HWP 79 was tested under typical conditions of OAT 35°C, IAT 27/ 19°C, EWT 30°C with LWT ranging from 35-45°C.

A 5°C increase in LWT results in water flow rates down from 0.53 l/s to 0.25 l/s and a pressure drop decrease from 70kPa to 17kPa. This graph illustrates no significant corresponding change to duty power & EER.

It can be seen that increasing the temperature differential across the condenser to 10°C has minimal effect on the duty or EER of the units, the increase in LWT occurs at system design conditions with the majority of operating conditions at slightly lower total system capacity than design conditions.

The reductions in pressure drop achieved by increasing the LWT up to a 10°C differential temperature is considerable, enabling a reduction in both pipe and pump sizes throughout the building leading to reduced costs in capital equipment and running costs.

Fawkner Residences is an upmarket residential development at 499 St Kilda Rd Melbourne. It's a great example of how the clever design of the HWP heat exchangers produced a significant reduction in total system installation costs.

For the Fawkner Residences project, the consultants chose to use Temperzone ThermoShell Water-Cooled Package Units for each apartment. The much lower water flow required by HWP ThermoShell units had a dramatic impact on the system design and installation cost.

Lower water flow rates enabled the design of the main water riser to change from steel, to copper. This negated the need for expensive offsite pre-fabrication, special lifting apparatus and higher labour costs.

In addition to the reduction of water pipe diameter, the reduced water flow required allowed the use of much smaller pumps and associated wiring and drivers.

Delta T changed from 5.5 to 11.5 on average.

Flow rate reduced from approximately 70 l/s to approx. 33 l/s.

Original design pump sizes were 2 x 18.5kW pumps, revised design reduced them to 2 x 11kW pumps.

Original design required a main 250mm steel riser, before tapering down. Revised design reduced main riser to 150mm copper.

Learn more about our Fawkner Residences case study, here.

ThermoShell's wider water temperature operating range offers greater flexibility when retrofitted into older installations.

In buildings where the condenser water loop is over 15 years old electric heating was widely used. As these buildings lack boilers, the addition of reverse cycle units can lead to the problem of unstable operation in heating mode.

In contrast, ThermoShell enables a wider water temperature operating range, allowing for greater flexibility in the condenser water loop and a maintenance of stable operation.

Tried and trusted throughout Australasia, Temperzone water-cooled units have a reputation for being energy efficient and highly durable.

Shan Li Tun Complex, Beijing (1363 units)

Kota Kasablanka, Jakarta (1070 units)

333 Collins St, Melbourne (160 units)

Billion Centre, Hong Kong (747 units)

ThermoShell technology –innovative high-efficiency heat exchange technology.

Increased Efficiency

Lower water flows and pressure drops, –leading to lower capital costs

Wide EWT range with retrofit flexibility

Long life, non fouling technology

Increased energy efficiency with EC fans

Available from 3.5kW to 101.6kW

Inbuilt control of the regulating valve for closer control and optimal efficiency

Control via 0-10VDC from UC8 to modulating water valve

Control via UC8 to a simple open/close water valve

Ability to integrate with building management systems (BMS)