Temperzone In-line design, a revolution in heat pump water heater solutions.

Temperzone's Aquanex MWH units are innovative boiler/electric heater bank replacement systems combining variable capacity inverter compressor and BLDC pump technologies to efficiently maintain a constant supply water temperature of between 25°C to 55°C at varying water flow rates to meet the required demand. Integrated in-line, they do away with conventional primary / secondary heating loops. Applications include radiator panels, fan coil space heating, fresh air tempering and process heating.

MWH Space Heating

Capacity Range (heating):

- MWH 900 with EVI 89.3 kW net (range: 21 ~ 105 kW)

- MWH 900 without EVI 77.5 kW net (range: 22.3 ~ 91.9 kW)

- MWH 2000 with EVI 140 kW net (gross range: 14 ~ 201 kW)

- MWH 2000 without EVI 154 kW net (gross range: 14 ~ 220 kW)

Refrigerant:

- R32 Refrigerant

Inverter In-line Design

- No need for intermediate buffer tanks*

- Reduction in required pump power

- Reduction in piping required

- Most energy efficient system

- Reliable long life system

- Low service / maintenance requirements

- Compact Design

Temperzone Inverter Inline Design

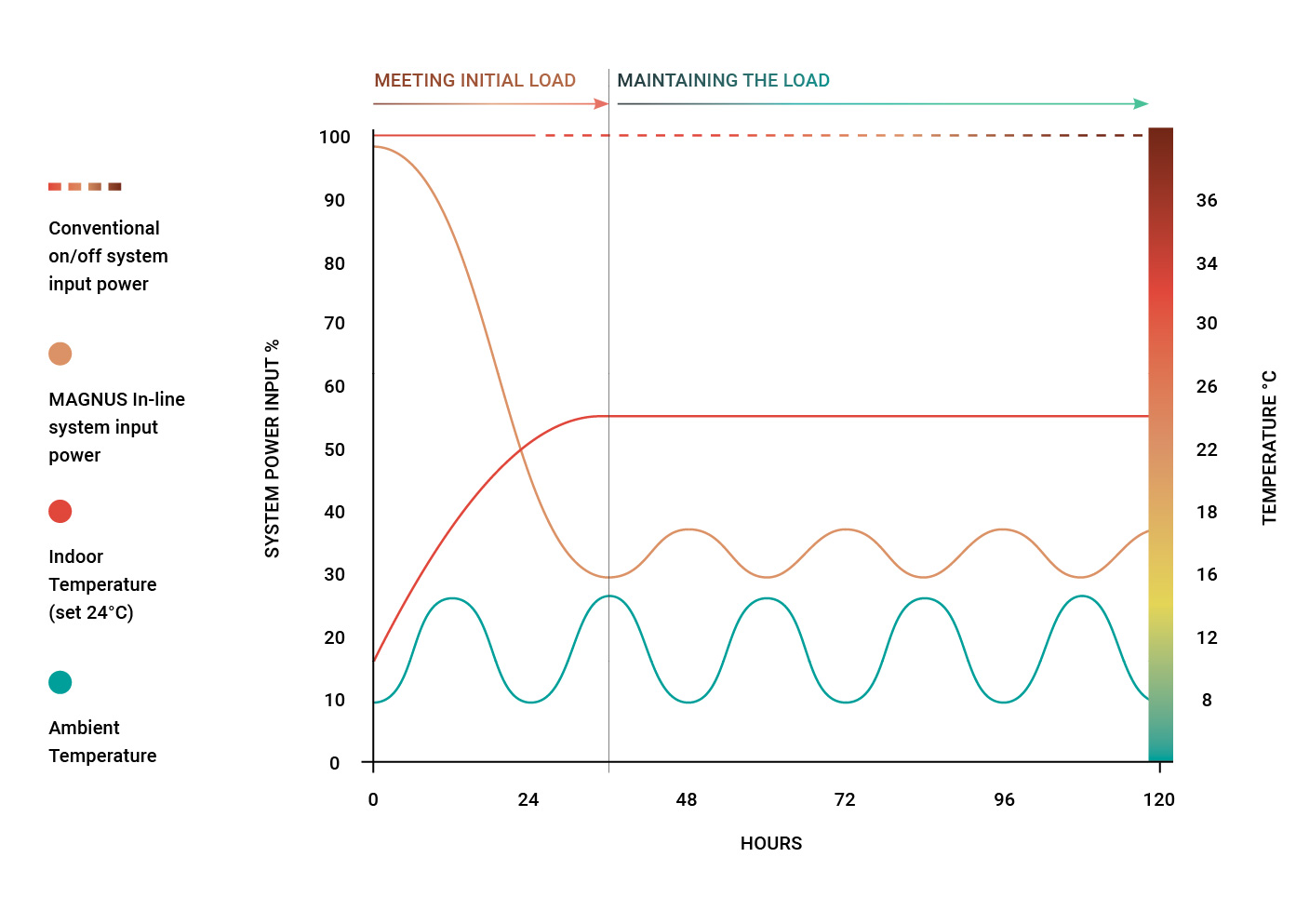

In-line systems take full advantage of inverter compressor technology which increase in efficiency at part load operation. Aquanex Inverter heat pumps supply heated water at a constant of between 25°C to 55°C while variable speed BLDC pumps (optionally provided) control delivered capacity by varying the flow rate. This in-line design eliminates the requirement for a intermediate buffer tank* and primary / secondary circuits. The inverter compressor, as the load is met, significantly reduces energy consumption by turning itself down to operate at part load while still maintaining the heating requirements of the application.

*inline tanks to meet minimum system water volume requirements may be required.

Refer application manual.

Inefficient Conventional Systems

A conventional heat pump, typically operates at high speed turning itself on and off as the buffer tank requires heating. This method is inefficient as the buffer tank must be continually overheated beyond the demand setpoint due to the cooled return water mixing with heated water in the intermediate buffer tank.

Designed for Efficiency

In-line inverter systems have reduced total system power input. The inverter compressor, as the load is met, significantly reduces energy consumption by turning itself down to operate at part load. A conventional heat pump, typically operates at high speed turning itself on and off as the buffer tank requires heating. This method is inefficient as the buffer tank must be continually overheated beyond the demand setpoint.

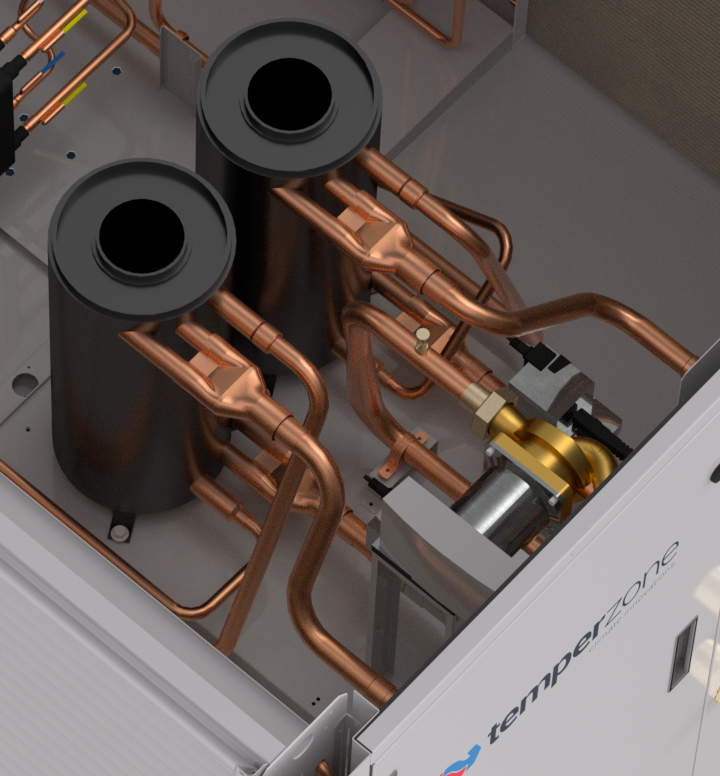

Enhanced Vapour Injection (EVI)

Specially designed for colder climates, EVI technology provides the assurance that comfort levels will be maintained at low ambient temperatures.

EVI hardware works in combination with Temperzone’s proprietary UC8 software, to inject vapour directly into the scroll plate of the compressor. The resultant cooling on the compressor provides increased capacity in cold conditions.

- All year round performance

- Increased capacity at low ambient temperature (down to -10 °C)

- Unlocks the full potential of the compressor

- Guarantees compressor protection under high loads

Lower Capital Investment

In-line systems directly provide the capacity required for the application eliminating the need for intermediate buffer tanks and primary / secondary circuits. This approach reduces installed system capital costs, and significantly increases system efficiency, especially under part-load conditions, resulting in one of the most cost-effective water heating systems on the market.

- No need for intermediate buffer storage tanks*

- Reduction in required pump power

- Reduction in piping diameter required

- Low service / maintenance requirements

- Most energy efficient system

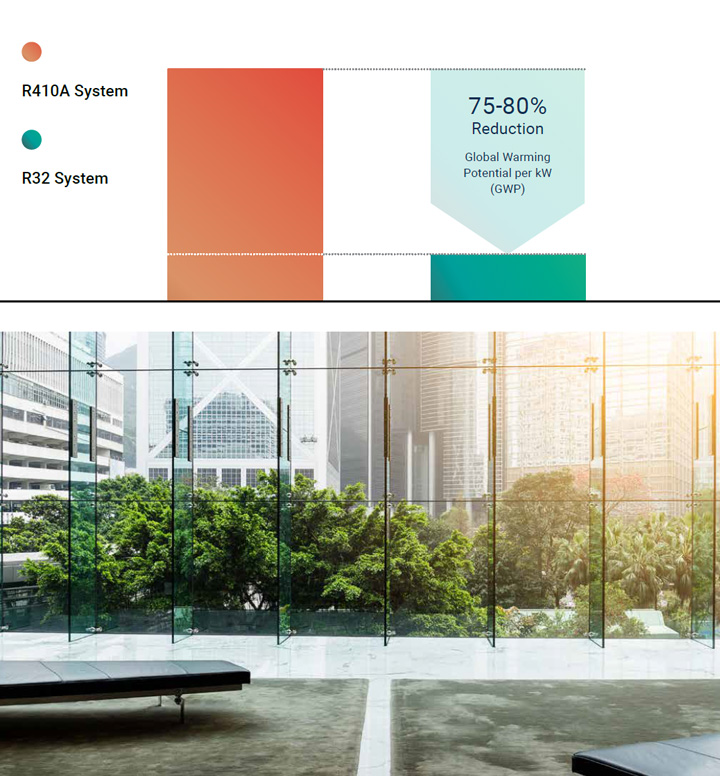

Lower Global Warming Potential

Due to a smaller refrigerant charge and a reduced refrigerant GWP of 677, these R32 refrigerant systems represent a 75-80% reduction in overall GWP per kW of heating when compared to R410A systems (GWP 2088).

As higher GWP refrigerants face increasing cost due to emissions tax levies the specification of R32 systems will represent a significant reduction in the future costs associated with owning and maintaining these systems.

Designed to Operate Reliably, Longer

In-line systems are low maintenance, with low service requirements. Its ThermoShell® heat exchanger, unlike traditional heat exchangers, are fouling resistant. Also, the advanced unit controller combined with application specific design uniquely enables the compressor to constantly operate within its design limits improving unit life.

Advanced System Controls

Controlled by Temperzone advanced UC8 and a PLC Controller.

- Control for stage control, De-ice management, air temperature control for single load.

- The PLC controller offers ability for BACnet or MODBUS coms via ethernet.

- Integrated system protections

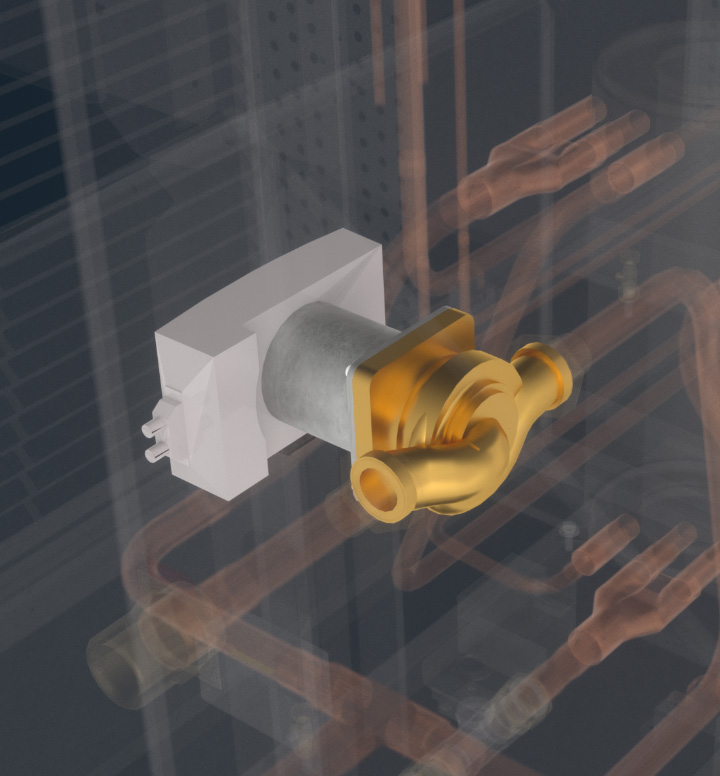

BLDC Variable Speed Pump

Highly efficient optional variable speed pumps effectively control the heating capacity of the system by varying the water flow rate. The smart pump has a EC motor that reduces energy use by around 50%.

Dual Electronic Expansion Valves (EEV)

Dual EEV's, benefits include;

- EEVs enable improved efficiency and reduced operating costs at part-load conditions.

- They also facilitate maximised energy savings during the shoulder seasons – periods in which air conditioning systems often run at part-load.

- Fast and precise control of superheat.

Inverter Compressor Technology

Inverter compressors only use the amount of energy to suit the operating condition maximising your energy efficiency.

- Soft starting, using much less power at start up.

- Full inverter compressor range from 16-100% compressor speed.

- Reduced amount of start/stop for long life operation.